By Charlie Hoherd, Vice President Roscoe Moss

The Roscoe Moss Company is a global leader in the manufacturing of water well casing and screens. Originally founded in 1926 in Los Angeles, California by Mr. Roscoe Moss as a water well drilling contracting company, it also manufactured its own steel water well casing and screen as a means to meet market demand. Over the next several decades, the company drilled thousands of wells throughout the western United States, many of which are still in production today. Mr. Moss led the company until his passing in 1977, at which point his two sons, Rocky and George, took over and continued to expand the company’s reach which included water well projects in South America, Asia, the Middle East and Africa.

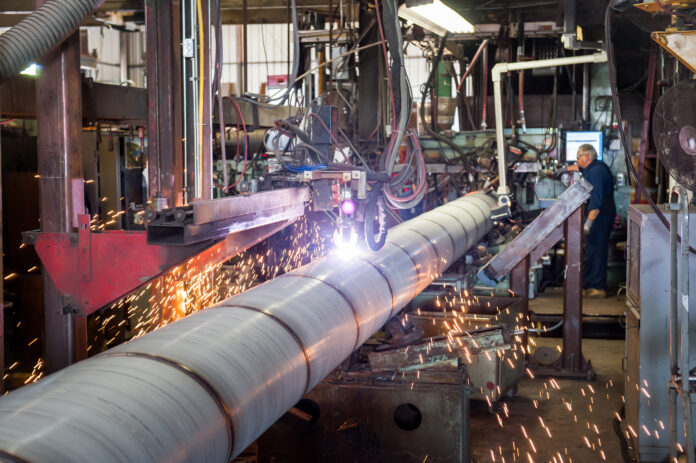

In the mid 1980’s the company exited the water well drilling business as a contractor, choosing to focus on the design and manufacturing of steel well casings and screens. Despite the passing of Rocky Moss in 2010 and George Moss in 2021, the company continues to be owned by the Moss family. Today the company maintains the proud tradition of having their products be manufactured in the USA at their Los Angeles facility. The company also operates a service facility in McFarland, located at the junction of Hwy-99 and Hwy-46.

Roscoe Moss Company employees a team of professionals that are experts in the field of hydrogeology, well drilling & construction, engineering, fluids control, and metallurgy and corrosion. This team works in tandem with water well drilling contractors, owners, and consultants to ensure the proper materials are selected to produce the most efficient and longest lasting water well for the owner.

In the world of water wells, there is a choice between professionally engineered screen such as Louvered, and generic, inefficient options such as mill slot or torch cut. Roscoe Moss Company’s recognizable Louvered well screen is known throughout the industry to have the highest collapse strength and least prone to clogging and failure compared to any other generic screen option.

Every water well is unique so the Roscoe Moss Company strongly believes no single steel is appropriate for every well installation. Site specific variables that help determine the proper steel selection include ground water quality, well depth, and anticipated operational life of the water well. Because of this, the Company manufactures water well casings and screens in a variety of corrosion resistant steels, such as Copper Bearing, High-Strength Low-Alloy (HSLA), and various grades of Stainless Steel.

“Here at Bakersfield Well and Pump (BWP) we’ve used many types of casing perforations for water well installations”, said John Zimmerer, General Manager Bakersfield Well and Pump. “Most of our Ag wells have been either louvered or mill slot and the common question by most of our customers, ‘Which type of casing perforation is better?’

“It’s our observation Louvered perforations produce more water than the generic mill slot option. BWP prefers to install larger slot louvered perforated casing verses mill slot casing with the same size gravel pack, because this provides increased open area. I feel the airgap the louvered casing provides improves the open area because the gravel has less plugging of the perforation.”

“Cost wise,” continued Zimmerer, “the louvered casing can be slightly more expensive than the mill slot. A mill slot can be easier to clean but must be done so much more frequently than a louvered screen because the mill slots tend to plug more quickly. Regardless, any good contractor must rely on a strong product, and there is no stronger screen option than Roscoe Moss louvered screens.”

Leaning on its almost 100 years of experience, Roscoe Moss Company willingly provides technical information to the industry and water well owners. In the Central Valley, common issues for well owners include subsidence and well collapse. To combat these issues, Roscoe Moss Company manufactures specific components such as compression sections, which act like a shock absorber for your well and prolong its useful life. Additionally, case studies and technical reports covering topics such as corrosion mitigation, subsidence, well rehabilitation, maximized well efficiency, and proper gravel pack selection to prevent sanding issues are available free to download from their website www.roscoemoss.com or by contacting any member of the Roscoe Moss Company team directly.

For any questions related to drilling a well, proper steel selection, or efficient well design, please contact Tom Herring or Keith Jagels in the company’s McFarland office at 661/393-5756.

DISCLAIMER OF RESPONSIBILITY; Waterwrights.net strives to provide its clients with the most complete, up-to-date, and accurate information available. Nevertheless, Waterwrights.net does not serve as a guarantor of the accuracy or completeness of the information provided, and specifically disclaims any and all responsibility for information that is not accurate, up-to-date, or complete. Waterwrights.net’s clients therefore rely on the accuracy, completeness and timeliness of information from Waterwrights.net entirely at their own risk. The opinions expressed in this report are those of the author and do not represent any advertisers or third parties.

ALL RIGHTS RESERVED. Copyright 2022 by www.WaterWrights.net/DAW